Additive manufacturing is not yet good

enough to make a car or an iPhone, but it is already being used to make

specialist parts for cars and customized covers for iPhones. Additive

manufacturing is only one of a number of innovative production equipment

leading to the factory of the future. Conventional production equipment is

becoming smarter and more flexible too.

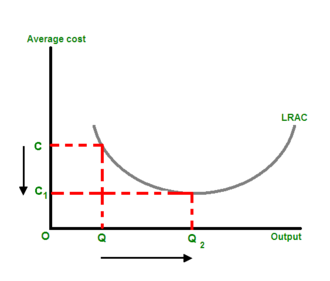

For example, Volkswagen is implementing a

new production strategy called MBQ. By standardizing the parameters of certain

components they hope to be able to produce all its models on the same

production line (Again economies of scale).

Factories are becoming vastly more

efficient. Nissan’s British factory in Sunderland, opened in 1986 is now one of

the most productive in Europe. In 1999 it built 271,157 cars with 4,594 people

(59 cars per capita). Last year it made 480,485 cars with just 5,462 people (88

cars per capita).

As the number of people directly employed

in making things declines, the cost of labor as a proportion of the total cost

of production will diminish too. This will encourage makers to move some of the

work back to rich countries, not

least because new manufacturing techniques make it cheaper and faster to

respond to changing local tastes.

The materials are changing as well.

Carbon-fibre composites, for instance, are replacing steel and aluminum.

Sometimes it will not be machines doing the making, but micro-organisms that

have been genetically engineered for the task. Software are going smarter. And

the effects will not be confined to large manufacturers, much of what is coming

will empower small and medium-sized firms and individual entrepreneurs.

Launching novel products will become easier and cheaper. Communities offering

3D printing and other shared production services are already forming online.

The consequences of all these changes

amount to a third industrial revolution,

as The Economist wrote in April 2012. The first began in Britain in the late 18th

century with mechanization of textile productions. The second began in America in the early 20th

century with the assembly line and the era of mass production.

As manufacturing goes digital, a third

great change is now gathering pace. It will allow things to be made

economically in much smaller numbers, more flexibly and with a much lower input

of labor. The first two industrial revolutions made people richer and more

urban. The third?

Source: The Economist, Special Report on Manufacturing and Innovation,

A third industrial revolution, April 21st 2012.